NJII Defense Printed Electronics staff, located at the Landing 360 COMET Center, have been working with the Institute of Printed Circuits (IPC) Additively Manufactured Electronics (AME) Subcommittee D-67 to establish standards for AME. Standards are used to ensure that printed electronics processes conform to acceptable values. Once standards are published, they can be used to define detailed specifications for inspection, qualification and certification. In short, standards are the building blocks to increase the manufacturing readiness levels (MRL) of new technology.

Our team worked on two different IPC task groups; AME Coupons, and the Acceptability of AME Specification. The team developed and printed test coupons with IPC task group members. During regular meetings, the task group reviewed the coupon designs, performed necessary modifications, and worked with IPC to plan future courses of action.

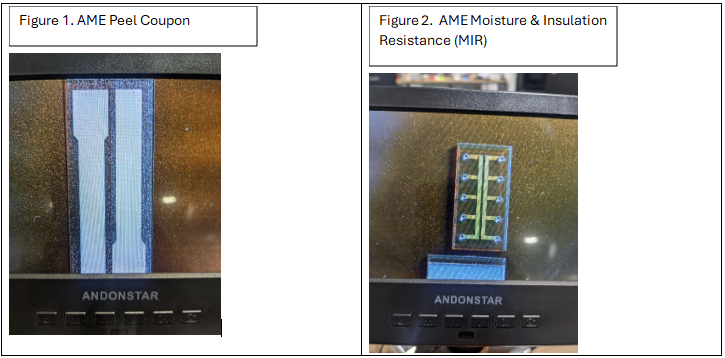

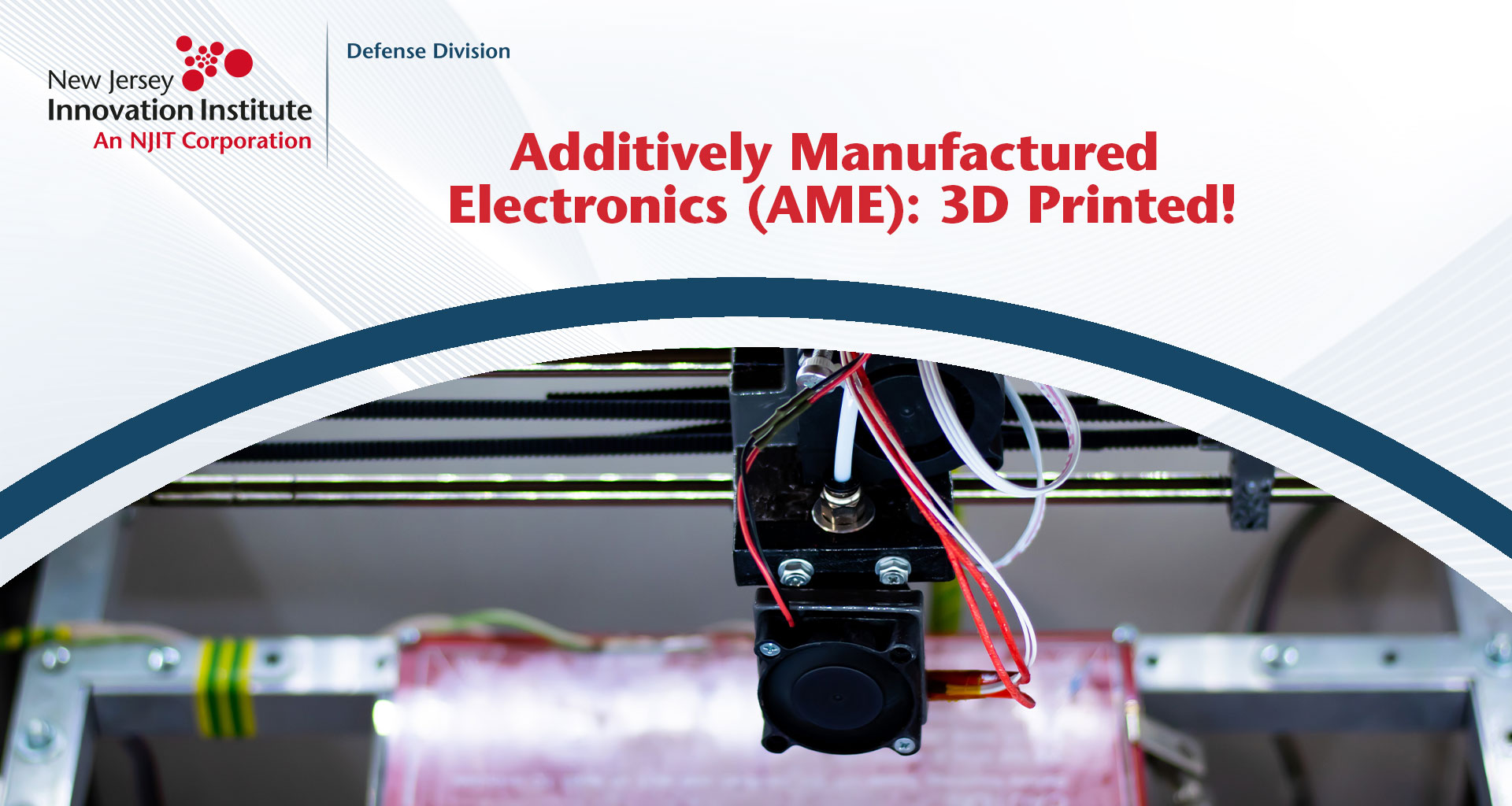

To date, a suite of 11 different test coupons have been developed to validate AME properties on various equipment types. Some of the factors assessed are: SMT + THT attachment, Layer bond strength, Electrical characterization of embedded components (coax, twisted & differential pairs, 3D traces), Conductive peel strength, Moisture and insulation resistance (MIR) , Thermal Stress, and Z-axis registration. Some of these are shown in Figures 1 & 2 below.

Soon, the task force will be reviewing test methods for printed electronics and the Acceptability of AME Specification. Following the review, documents will be released to other IPC task groups and the public for comments and critique.